Like the static mounting bracket, these mounting brackets slide over the body of the linear actuator and are attached by tightening two bolts, but unlike the static mounting bracket, these mounting brackets allow the actuator to pivot.

#Mounting brackets series

Our MB50 Mounting Brackets are designed to be used with our Bullet Series 50 Cal Linear Actuators ONLY and are used to mount these actuators from the body.

#Mounting brackets tv

This mounting bracket, used in conjunction with our other brackets, would be ideal in applications like pop-up drawers or custom TV lifts. This bracket was specifically designed to work with our Premium Actuators and Optical Feedback Premium Linear Actuators. Our Premium Base Mounting Bracket converts our Premium Actuators to a column lift style Actuator. These brackets are made of sturdy aluminum and are rugged enough to be used in heavy-duty applications such as in yachts and automobiles. They are built to fit over the body of these actuators to ensure they do not rotate and can be used in conjunction with our MB1 bracket.

Our MB6 Static Bracket is designed to be used with Classic Rod Linear Actuators ONLY. These brackets simply slide over the body of the linear actuator and are attached by tightening two bolts. Static brackets are attached to the body of the linear actuator and are used to keep the body of the linear actuator stationary. Static – MB6Īnother commonly seen mounting bracket is the static mounting bracket. These brackets also have an elongated mounting hole that allows for easy adjustment and installation. While our MB1-P clevis bracket handles up to 1000lbs and is designed to be used with our Premium Linear Actuators and our Premium High Force Linear Actuator. Our MB1 Clevis Bracket handles up to 5000lbs and is suitable for all of our Standard Classic Rod Style Linear Actuators and Mini Linear Actuator lines. These brackets have a clevis and pin design and are built to be attached to either end of a suitable linear actuator. One of the most commonly used mounting brackets for linear actuators is the clevis bracket. Why is that important? well once the Actuator begins to move the object it is designed to move it is likely that this component itself is also pivoting around something, and so the Linear Actuator is required to rotate around its Fixed axis. However, the Actuator is allowed to pivot around each of those pins.

#Mounting brackets free

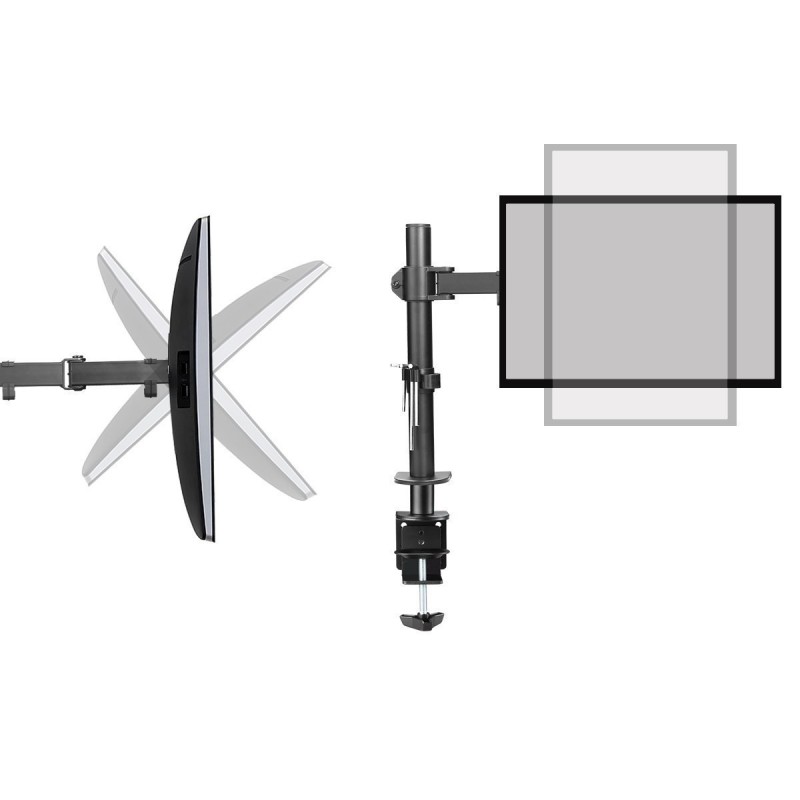

These common mounting methods consist of mounting the Brackets at each end of the linear actuator where both ends are free to rotate and pivot around the Clevis holes on each of the actuators.Īs you can see above the Actuator has the same bracket installed on each end of the Linear Actuator, and the cross pin slides through both the Bracket and the Actuator to create a solid connection between the two pieces. The most common method to mount your linear actuator is to use what is called Clevis Mounting Brackets. If you have any queries about our Mounting Brackets, get in touch and we can help you chose the best Brackets for your project.

The quality of our Mounting Brackets cannot be beaten. This makes the installation of your bracket easy as they are specifically designed for our actuators.

We have a Mounting Bracket for every imaginable project and have at least one designed specifically for each actuator type FIRGELLI sells. Finding the right mounting brackets can make a huge difference in how successfully your next project is. The upper approach plate slides into the brackets to provide a smooth entry from the ramp to the upper surface.While determining and selecting the right linear actuator gets most of the attention, choosing the right linear actuator mounting bracket is sometimes forgotten or hastily decided. When the ramp is not being used, it can be removed and stored inside while the brackets stay in place Z-Mount brackets are a great solution for mounting your ramp below a doorway. The brackets are screwed into the front of the structure and the upper approach plate slides into the space between the brackets.

Pictured below, Roll-A-Ramp’s custom Seg-Mount brackets provide smooth wheelchair access into this hunting cabin. The ramp upper approach plate drops into brackets.Mount to the front of a porch, deck or landing to have a smooth, flush entry and exit to your Roll-A-Ramp.Can be installed into wood, concrete or metal. These Z-shaped brackets allow your ramp to be level with the surface of your landing. The ramp’s standard upper approach plate slips into the bracket at 90-degrees and removes in seconds.

#Mounting brackets portable

Seg-Mount Brackets allow for easy mounting of your portable ramp to any landing surface. However, they can provide flexibility if you have space constraints.

0 kommentar(er)

0 kommentar(er)